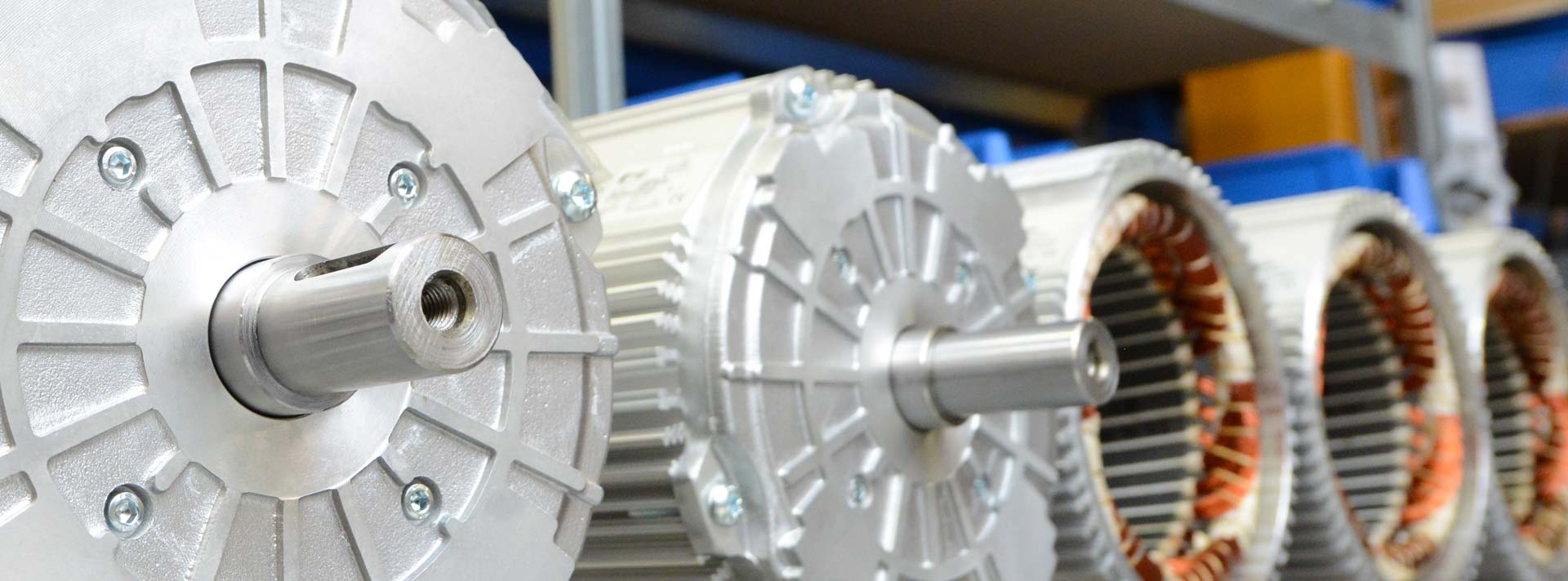

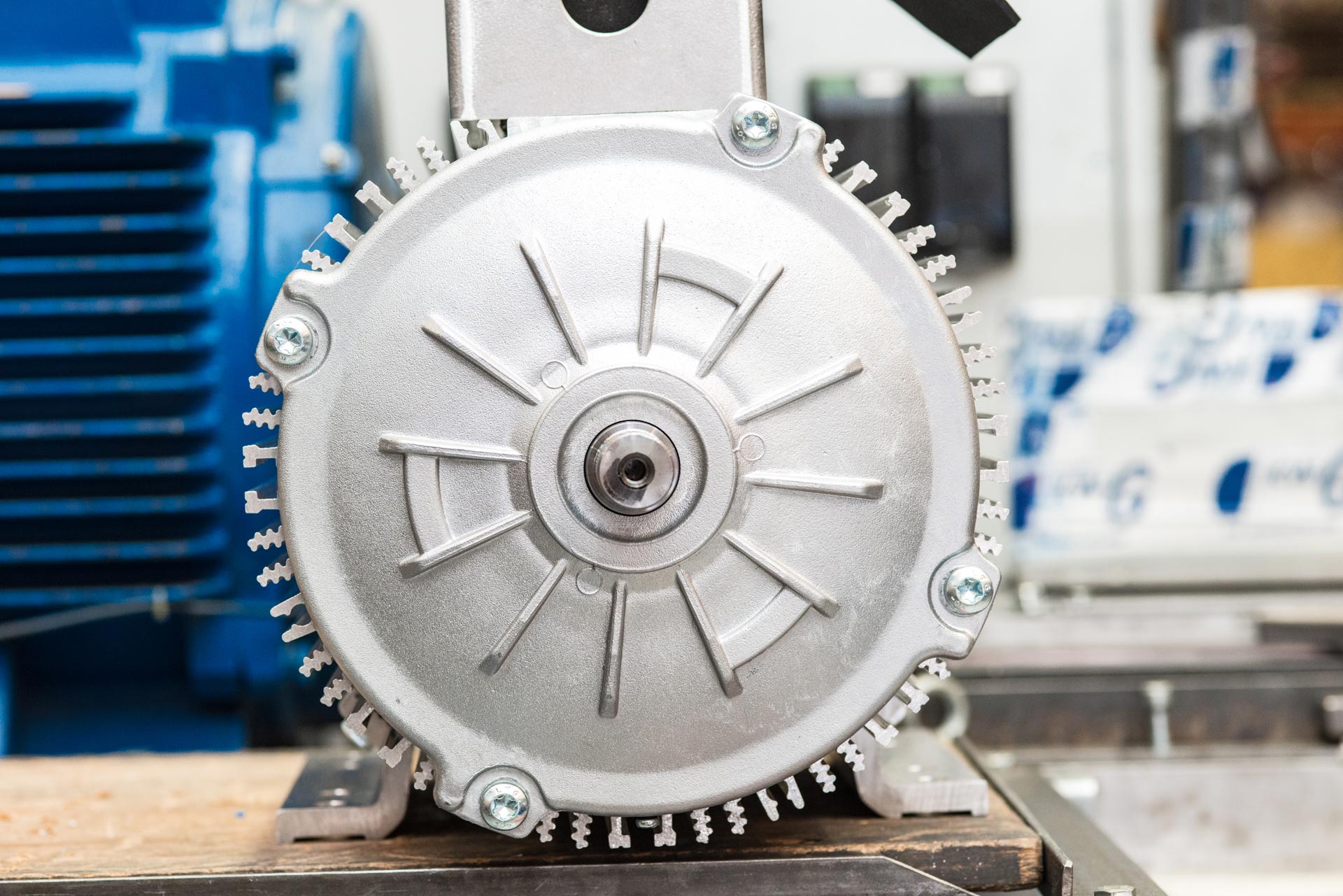

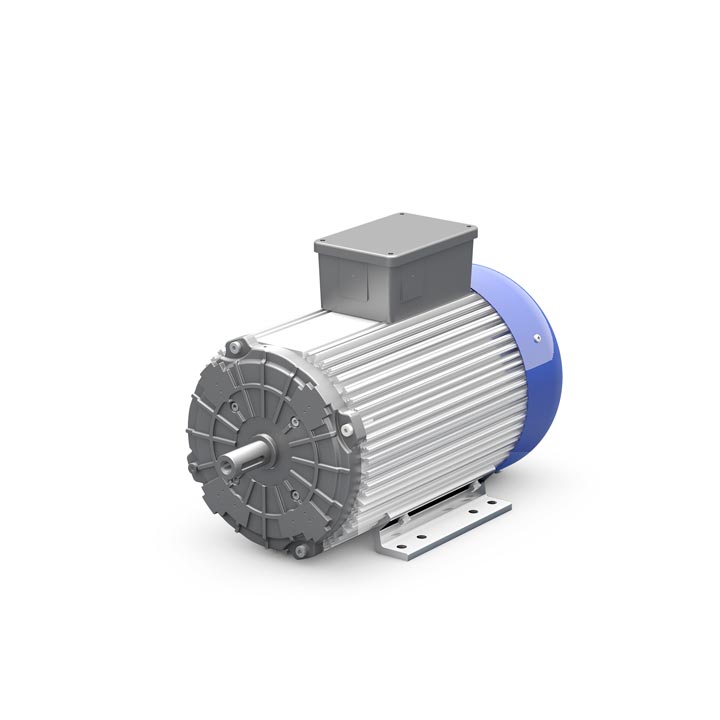

Synchronous Generator BG 132

- brushless

- self-excited

- integrated generator controller with standard CAN SAE 1939

- single and two bearing generators available

- 2-pole: 7–25 kVA, 3000 rpm – overspeed: 4500 rpm

- 4-pole: 5-15 kVA, 1500 rpm – overspeed: 3600 rpm

- universal flange connection options

- all standard single phase and three-phase voltages available

- IP54 - IP67

- maintenance-free up to 20,000 hours

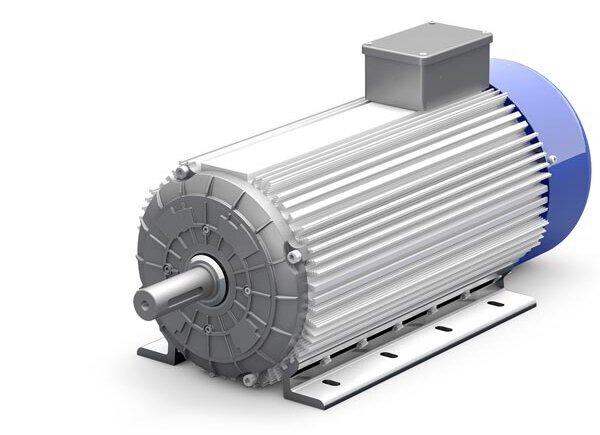

Synchronous Generator BG 160

- brushless

- self-excited

- integrated generator controller with standard CAN SAE 1939

- single and two bearing generators available

- 2-pole: 25-50 kVA, 3000 rpm – overspeed: 4500 rpm

- 4-pole: 20-40 kVA, 1500 rpm – overspeed: 3600 rpm

- 8-pole: 10–40 kVA, 3000 rpm (200 Hz) – overspeed: 4500 rpm

- universal flange connection options

- all standard single phase and three-phase voltages available

- IP54 - IP67

- maintenance-free up to 20,000 hours

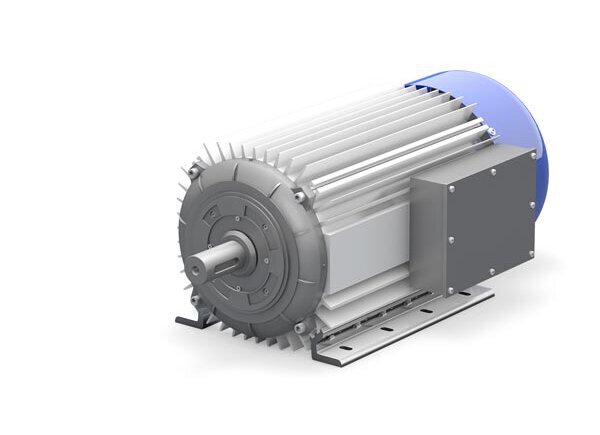

Synchronous Generator BG 200

- brushless

- self-excited

- integrated generator controller with standard CAN SAE 1939

- two bearing generators available

- 4-pole: 40-55 kVA, 1500 rpm – overspeed: 3600 rpm

- 8-pole: 60–80 kVA, 3000 rpm (200 Hz) – overspeed: 4500 rpm

- universal flange connection options

- all standard single phase and three-phase voltages available

- IP54 - IP67

- maintenance-free up to 20,000 hours

Synchronous Generator BG 250

- brushless

- self-excited

- integrated generator controller with standard CAN SAE 1939

- two bearing generators available

- 4-pole: 60-135 kVA, 1500 rpm – overspeed: 2800 rpm

- universal flange connection options

- all standard single phase and three-phase voltages available

- IP54 - IP67

- maintenance-free up to 20,000 hours

Synchronous Generator BG 280

- brushless

- self-excited

- integrated generator controller with standard CAN SAE 1939

- two bearing generators available

- 4-pole: 150-225 kVA, 1500 rpm – overspeed: 2200 rpm

- universal flange connection options

- all standard three-phase voltages available

- IP54 - IP67

- maintenance-free up to 20,000 hours

Synchronous Generator BG 355

- brushless

- self-excited

- integrated generator controller with standard CAN SAE 1939

- two bearing generators available

- 4-pole: 225-550 kVA, 1500 rpm – overspeed: 2200 rpm

- universal flange connection options

- all standard three-phase voltages available

- IP54 - IP67

- maintenance-free up to 20,000 hours

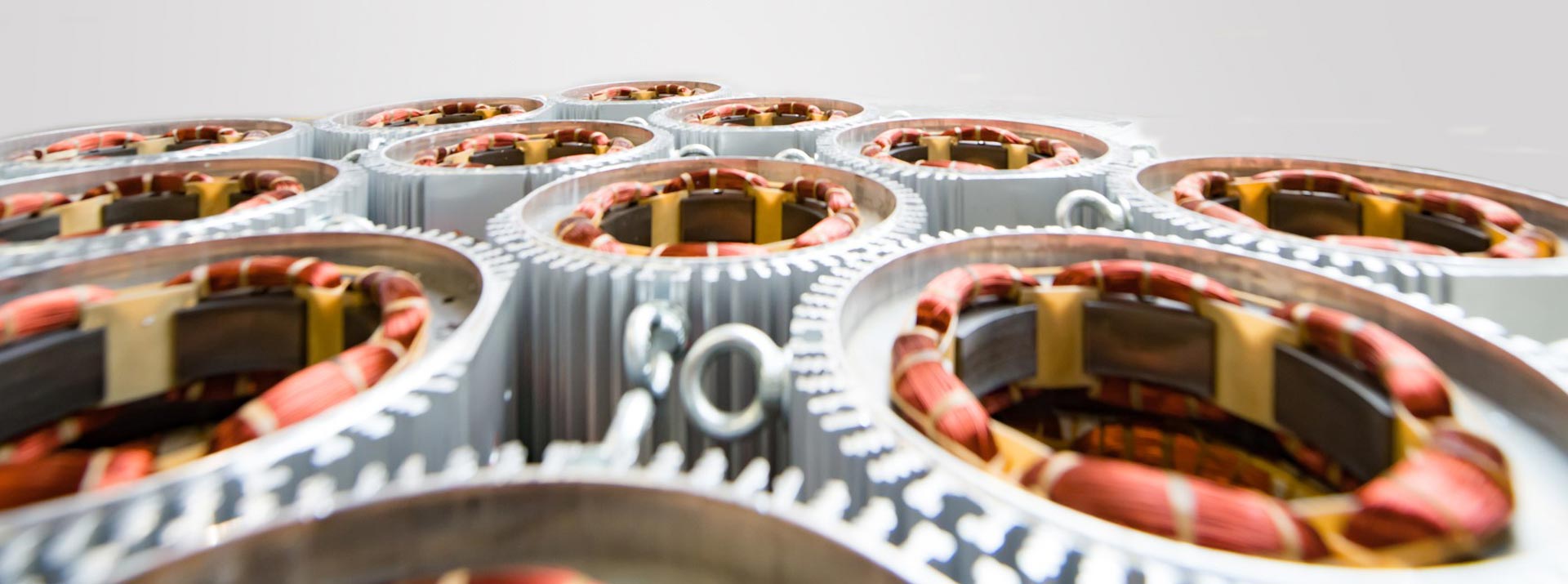

Generator for magnet plate systems GEMA

- brushless, self-excited, integrated generator controller with standard CAN

- single and two bearing generators available

- 2-pole: 9, 15, 20 and 30 kW, 3000 rpm – range: 2700– 3600 rpm

- 4-pole: 9, 15, 20 and 30 kW, 1800 rpm – range: 1800– 2500 rpm

- universal flange connection options for adapting hydraulic motors

- service-friendly design

- electronics box completely pluggable

- communication with “HMI” control unit via CAN

- At the same time it serves as a system diagnostic unit.

- user-friendly operation through pre-defined programmes with plain text display

- maintenance-free up to 20,000 hours

- IP54

GEMA Industrial

Magnet plate control for steel mills and mobile excavators

- compact complete control

- battery backup with integrated management

- relieable due to intelligent monitoring of the system

- control of several magnet plates in groups

Battery magnet plate system for material handler - BAMA

The BAMA system (battery magnet plate system) is a specially developed solution for material handlers that is powered by a high-voltage battery. It provides a modular coupling between the traction battery and magnet plates by means of galvanically isolated DCDC converters and magnet plate control. This technology provides an efficient and flexible solution for use in material handling technology and ensures reliable and powerful magnetic force control.

Key features of the BAMA system:

Precise visualization of system data:

The HMI operating unit clearly and precisely displays all relevant system data, enabling easy monitoring and control.

Preset, selectable programs:

The BAMA system offers pre-set programs that enable fast and efficient work with different materials. These programs ensure precise adaptation to the specific requirements of material handling.

Monitoring the insulation of the magnet plate:

By using the galvanically isolated DC/DC converter, the insulation of the magnet plate installation can be monitored independently of other systems.

Adjustable magnetic force:

The magnetic force can be conveniently adjusted via the HMI control unit at the push of a button to achieve the desired holding force for the respective application.

Wide input voltage range:

The BAMA system operates in the input voltage range of 520-1000V, which makes it easy to connect to various high-voltage battery systems.

Easy connection to higher-level control systems:

Thanks to CAN bus-based communication (SAE J1939), GEMA components can be easily integrated into existing control systems, enabling seamless interaction with other systems.

Maintenance-free and self-protecting:

The BAMA system is maintenance-free and features self-protecting electronics that ensure maximum safety in the event of cable breakage, short circuits, undervoltage, overvoltage and excess temperatures.

Power classes:

The BAMA system is available in the following power classes: 10kW, 20kW, 30kW

// Contact us for more information

Charging generator

- brushless

- self-excited

- integrated generator controller with standard CAN SAE 1939

- single and two bearing generators available

- universal flange connection options

- standard voltages from 12 – 96 V

- service-friendly design

- charging currents up to 350 A

- IP54

- maintenance-free up to 20,000 hours

Isolation Monitor ISO 5

- Insulation monitoring device AC/DC

- conform to the standard DIN EN 61557-8 (VDE 0431-8)

- CAN-Bus connection

- Flange and DIN rail mounting available

Service tool HMI

- Display of system statuses and measured values

- Control for magnetic disk systems

- Multiple I/Os and CAN bus

- Gateway function

- Graphic display of history values

Testing Systems

We offer customized testing systems:

- customized hard- and software

- fully automated test sequences

- modular "measuring box"

- "Plug and Play" via USB

- innovative complete solution / complete system

- SQL database connection

- simple software interface in Labview

- User-friendly operation

- any sensors, actuators and protocols

Fire department control cabinets

We offer customized fire department control cabinets:

- conform to the standard DIN 14686

- FireCAN optional

- analog or digital version

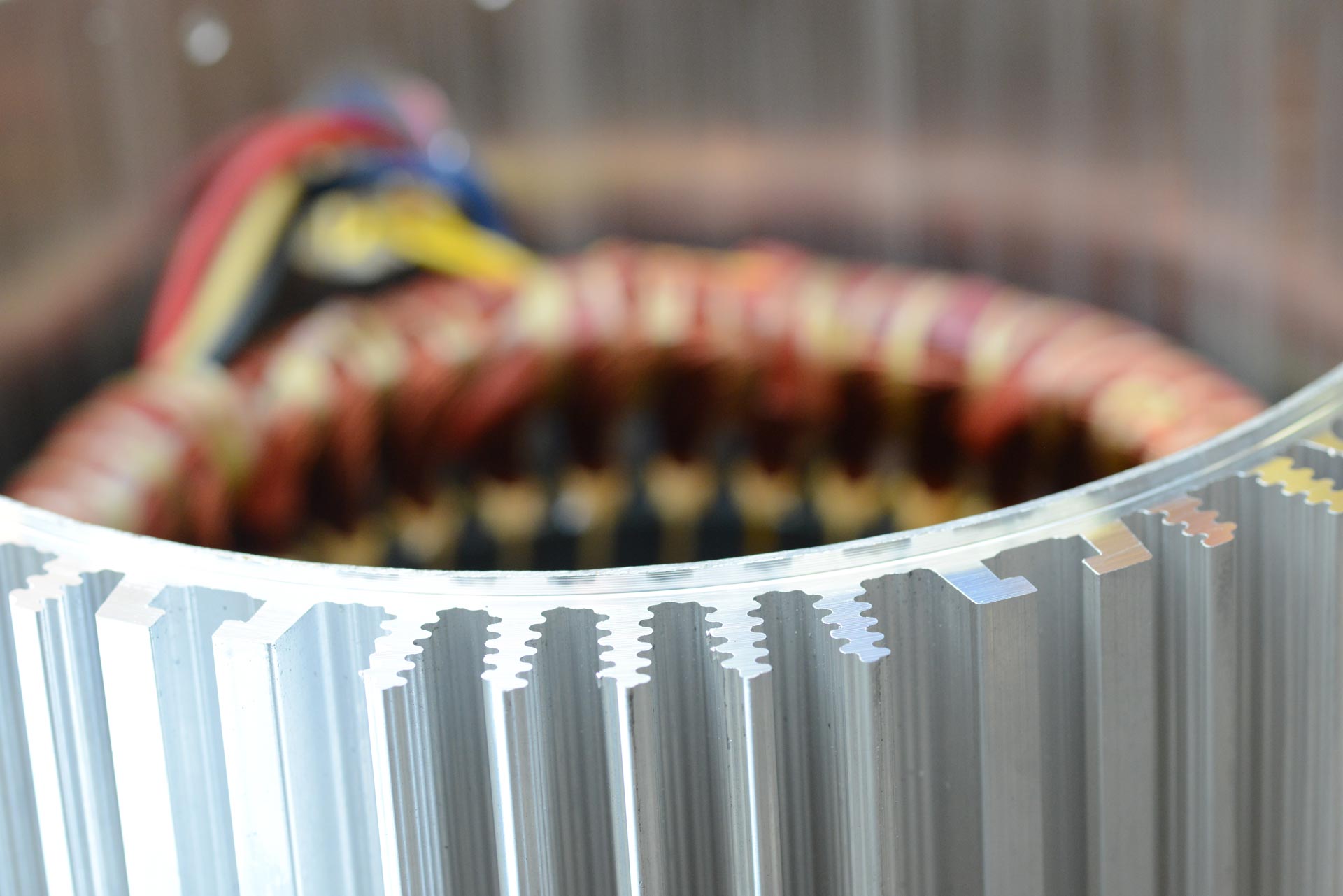

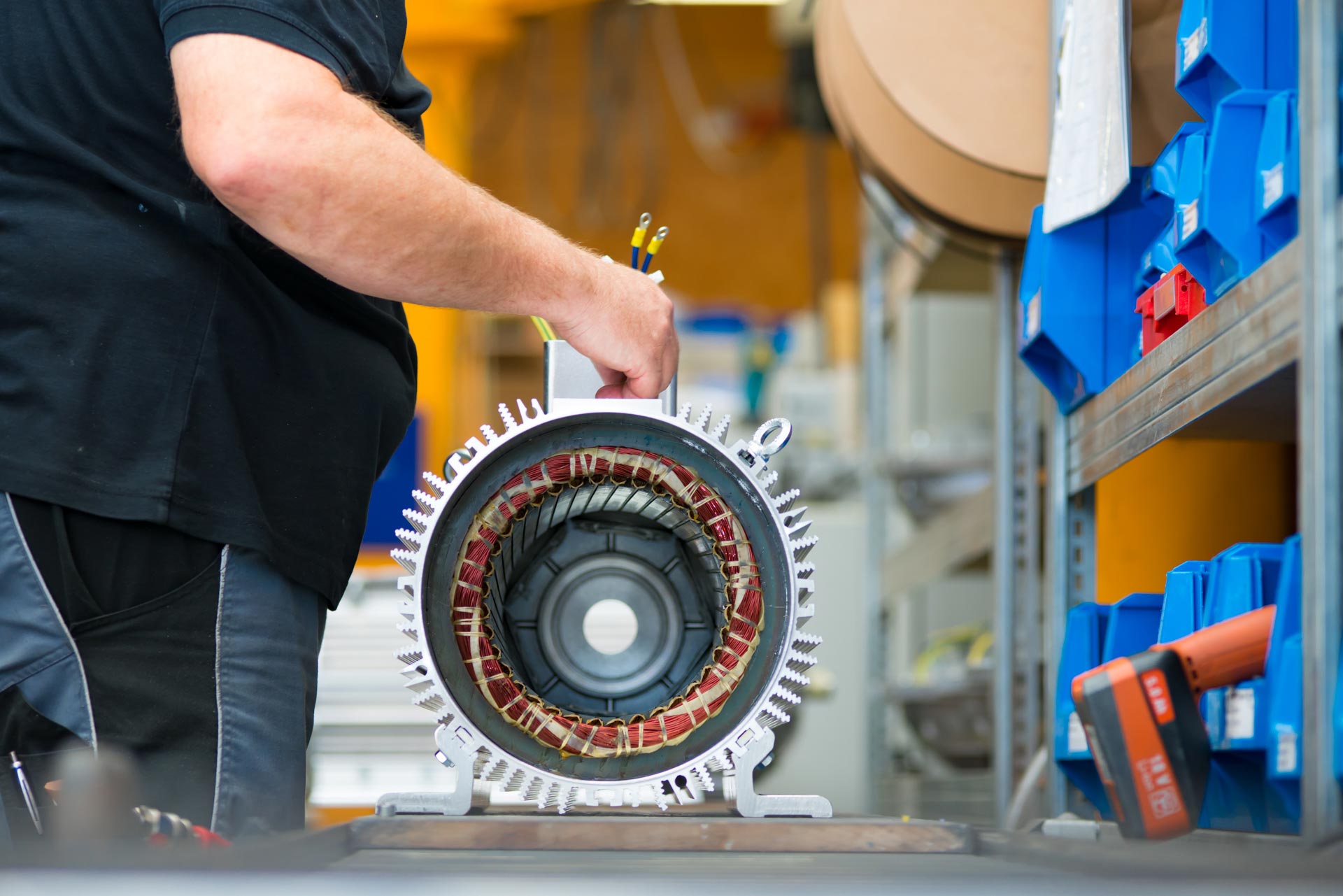

CUSTOMIZED SOLUTIONS

Customized design of electrical machines – a wide range of solutions for your requirements

The development of electrical machines requires customized solutions that are tailored to your specific requirements. With the FEM programs ANSYS Maxwell and a modern CAD design software, we offer you the ideal opportunity to design your machines efficiently and precisely.

Our solutions in detail:

Wide range of machine types: Regardless of the type of machine – whether synchronous machines, asynchronous machines or permanent magnet machines – we offer you an exact design that is tailored to your specific requirements.

Prototype and series production:

After the successful design of your machine, we offer you the opportunity to develop a functional prototype. In addition, we also support you in series production so that your machines can be produced reliably and in high quality.

Advantages of our solution:

High precision and efficiency:

Thanks to simulation with ANSYS Maxwell and integration into modern CAD systems, we ensure precise design and optimize your machines for maximum efficiency and service life.

Customization:

Every machine is specially designed and optimized for your requirements. From the first draft to simulation and real production – we offer you a customized solution.

Seamless integration:

The results from the simulation flow directly into the design and manufacturing, which simplifies and accelerates the entire development process.

Trust in our expertise:

With the latest simulation technology and extensive experience, we not only offer you precise design, but also implementation in prototypes and series production. We support you from the initial idea to the finished product and ensure that your machines are convincing in every respect.

// Contact us for customized advice and let us work together to turn your vision into reality!