KW-Generator at CONEXPO-CON/AGG 2026 – Las Vegas, March 3–7

KW-Generator, in partnership with Linz Electric Inc., is proud to announce its participation in CONEXPO-CON/AGG 2026, the largest construction trade show in North America, taking place in Las Vegas from March 3 to 7, 2026.

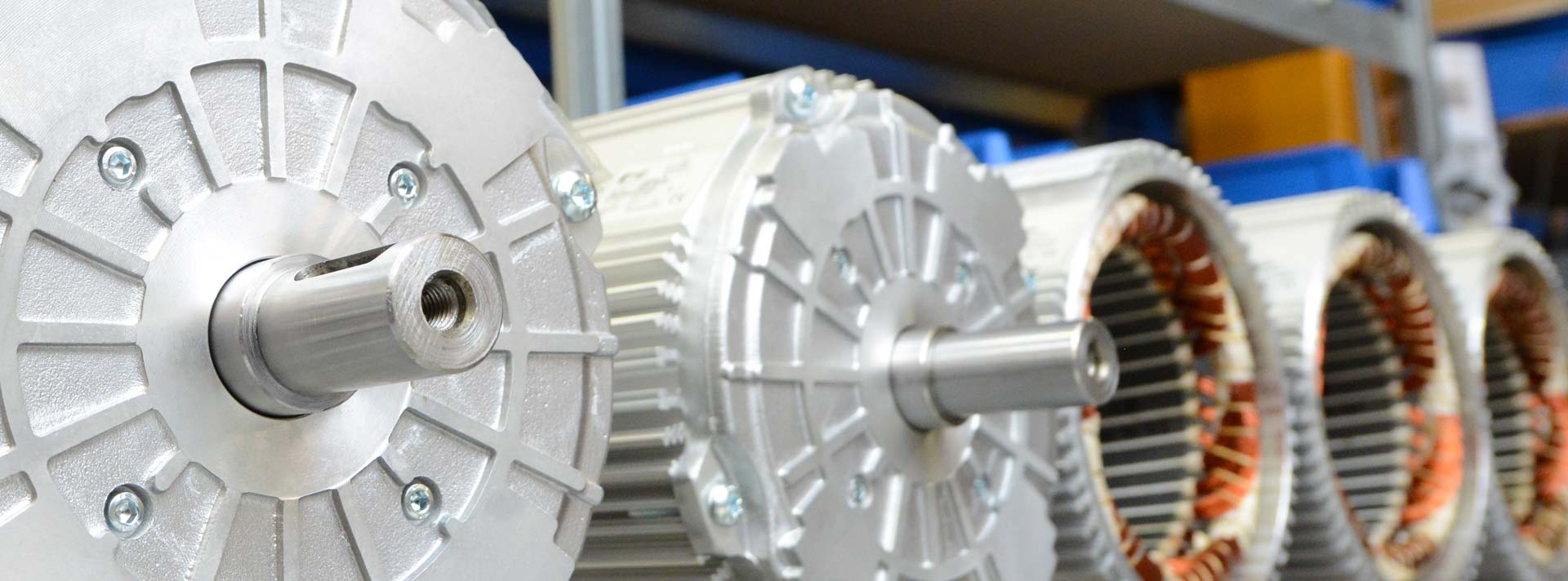

You’ll find us at the South Hall, Booth S63741, where we will showcase a wide range of KW-Generator and Linz Electric alternators, specifically developed for construction-related applications and heavy-duty equipment.

Our alternators are built to deliver reliability, efficiency, and robustness—qualities that are essential in the demanding construction industry. Visitors will have the chance to see firsthand how our technology provides dependable power solutions for machinery and equipment in this sector.

The KW-Generator team, together with Linz Electric Inc., will be on site to present the latest innovations, share technical expertise, and explore how our solutions can support the evolving needs of the construction market.

KW-Generator joins Linz Electric

A new chapter to grow together in the world of power generation.

KW Generator GmbH is proud to announce that Linz Electric – part of the Pedrollo Group – has acquired a 60% stake in our company. This step strengthens a nearly two-decade-long collaboration, built on mutual trust, a shared vision, and a constant focus on technological innovation.

This new phase allows us to take a significant leap forward: by joining forces with Linz Electric, we are ready to expand our ability to meet the demands of an increasingly global and demanding market. Together, we will offer one of the most comprehensive ranges of alternators worldwide, capable of addressing complex applications and supporting customers through the ongoing energy transition.

Becoming part of the Pedrollo Group through Linz Electric means KWG can now rely on a solid, international, and highly integrated industrial partner that shares our core values: quality, reliability, and customer focus. It is a strategic opportunity that allows us to further enhance our offering and face future challenges with confidence.

KW-Generator is entering a new phase of its journey, while remaining true to its German identity. Engineering excellence, highly specialized manufacturing, and a strong commitment to customization will continue to be the cornerstones of our approach.

Battery magnet plate system for material handler - BAMA

The BAMA system (battery magnet plate system) is a specially developed solution for material handlers that is powered by a high-voltage battery. It provides a modular coupling between the traction battery and magnet plates by means of galvanically isolated DCDC converters and magnet plate control. This technology provides an efficient and flexible solution for use in material handling technology and ensures reliable and powerful magnetic force control.

Key features of the BAMA system:

Precise visualization of system data:

The HMI operating unit clearly and precisely displays all relevant system data, enabling easy monitoring and control.

Preset, selectable programs:

The BAMA system offers pre-set programs that enable fast and efficient work with different materials. These programs ensure precise adaptation to the specific requirements of material handling.

Monitoring the insulation of the magnet plate:

By using the galvanically isolated DC/DC converter, the insulation of the magnet plate installation can be monitored independently of other systems.

Adjustable magnetic force:

The magnetic force can be conveniently adjusted via the HMI control unit at the push of a button to achieve the desired holding force for the respective application.

Wide input voltage range:

The BAMA system operates in the input voltage range of 520-1000V, which makes it easy to connect to various high-voltage battery systems.

Easy connection to higher-level control systems:

Thanks to CAN bus-based communication (SAE J1939), GEMA components can be easily integrated into existing control systems, enabling seamless interaction with other systems.

Maintenance-free and self-protecting:

The BAMA system is maintenance-free and features self-protecting electronics that ensure maximum safety in the event of cable breakage, short circuits, undervoltage, overvoltage and excess temperatures.

Power classes:

The BAMA system is available in the following power classes: 10kW, 20kW, 30kW

CUSTOMIZED SOLUTIONS

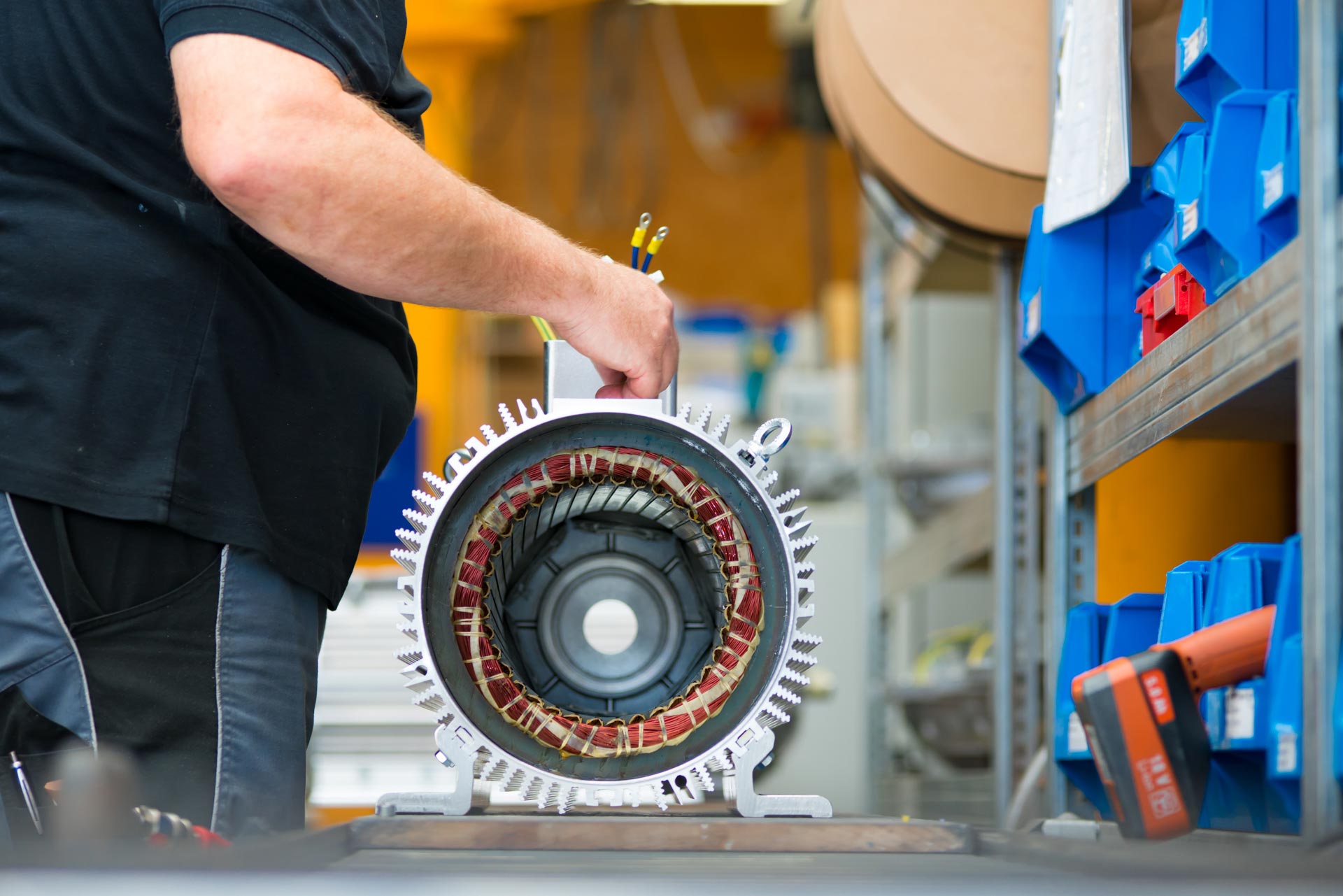

Customized design of electrical machines – a wide range of solutions for your requirements

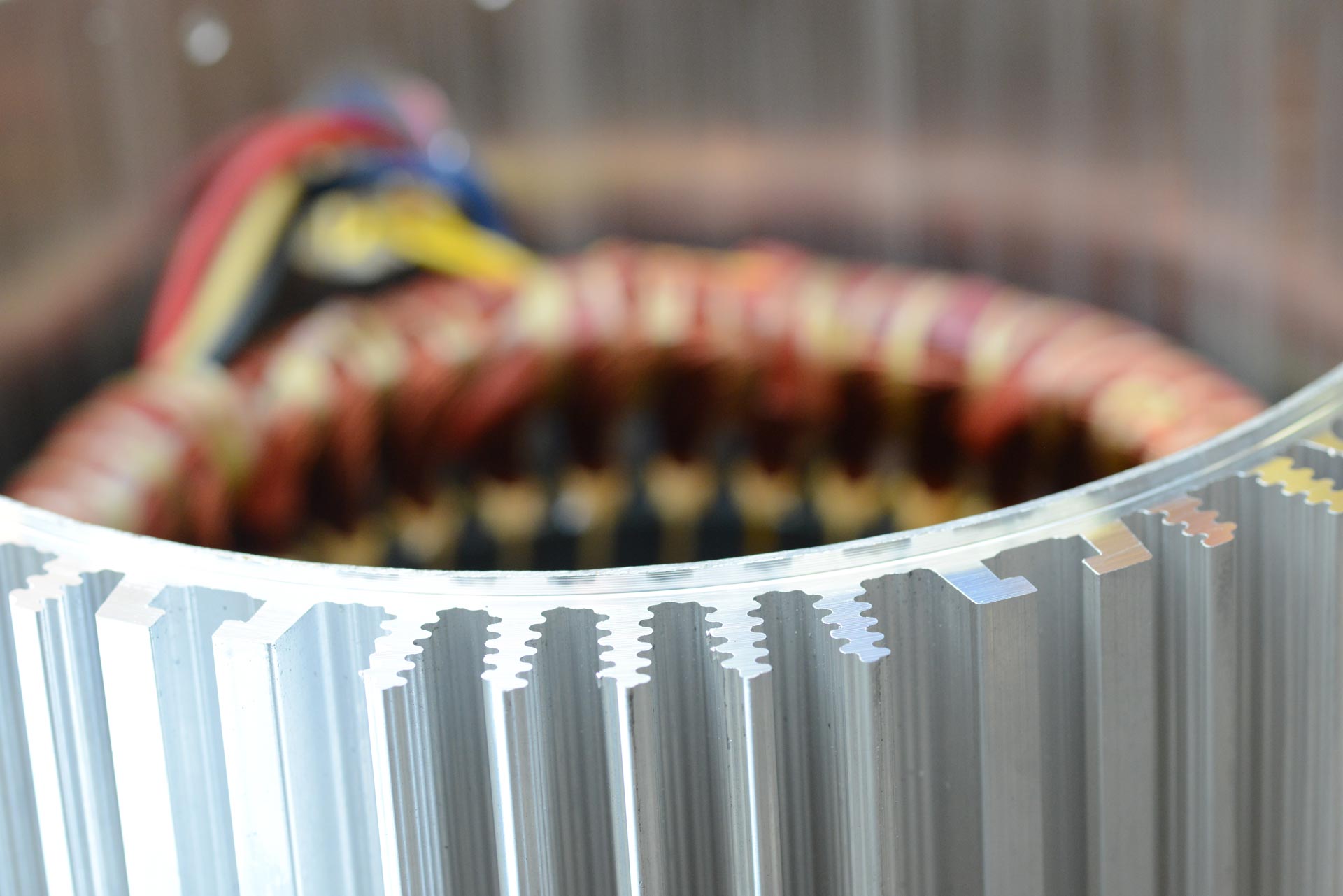

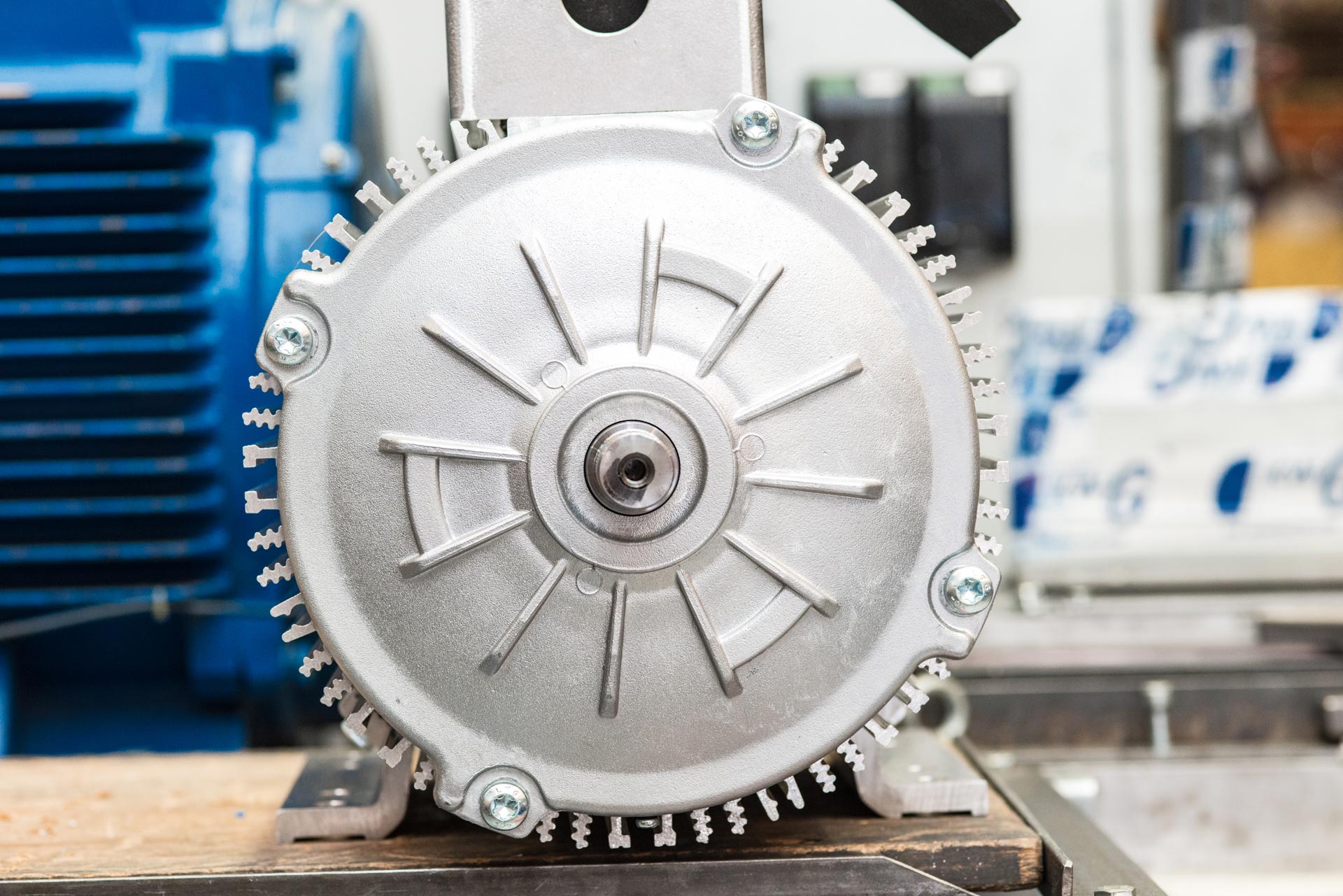

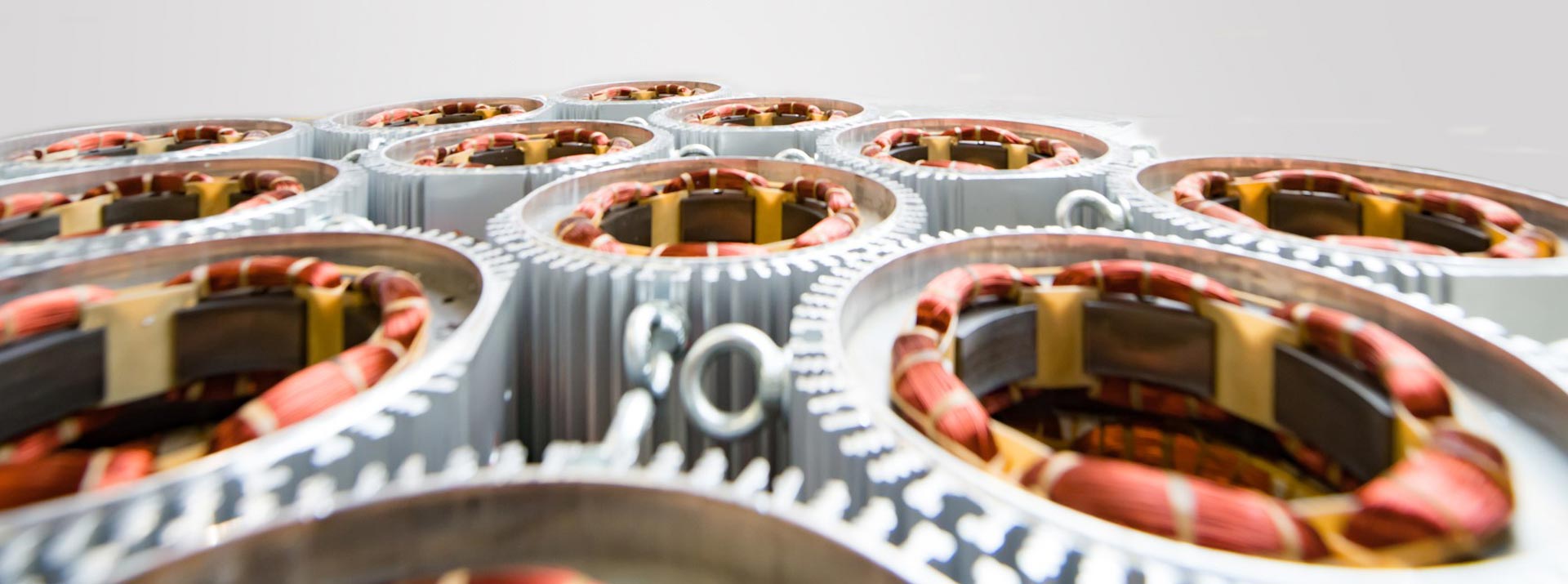

The development of electrical machines requires customized solutions that are tailored to your specific requirements. With the FEM programs ANSYS Maxwell and a modern CAD design software, we offer you the ideal opportunity to design your machines efficiently and precisely.

Our solutions in detail:

Wide range of machine types: Regardless of the type of machine – whether synchronous machines, asynchronous machines or permanent magnet machines – we offer you an exact design that is tailored to your specific requirements.

Prototype and series production:

After the successful design of your machine, we offer you the opportunity to develop a functional prototype. In addition, we also support you in series production so that your machines can be produced reliably and in high quality.

Advantages of our solution:

High precision and efficiency:

Thanks to simulation with ANSYS Maxwell and integration into modern CAD systems, we ensure precise design and optimize your machines for maximum efficiency and service life.

Customization:

Every machine is specially designed and optimized for your requirements. From the first draft to simulation and real production – we offer you a customized solution.

Seamless integration:

The results from the simulation flow directly into the design and manufacturing, which simplifies and accelerates the entire development process.

Trust in our expertise:

With the latest simulation technology and extensive experience, we not only offer you precise design, but also implementation in prototypes and series production. We support you from the initial idea to the finished product and ensure that your machines are convincing in every respect.

Contact us for customized advice and let us work together to turn your vision into reality!

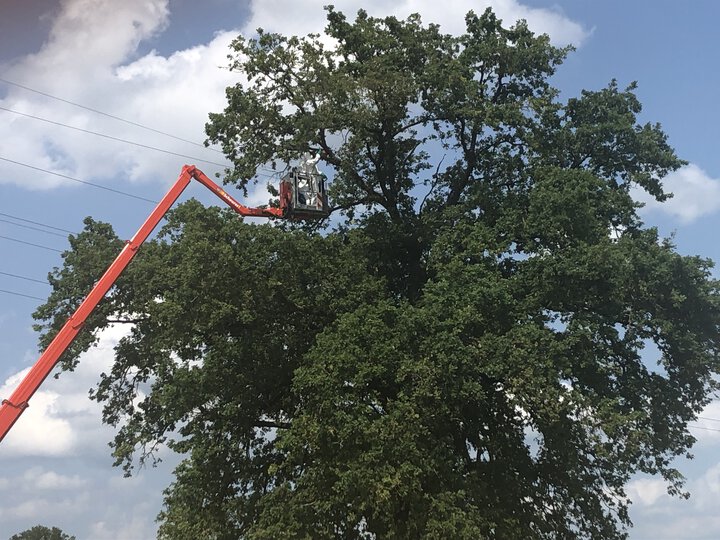

KWG makes power for the energy turnaround

The topic of energy is as topical as never before, every reduction of CO2 makes the future of our planet better. Diesel will soon be history, and the end of conventional combustion engines is within reach, electric energy is in demand and attractive as never before. KWG gives "gas" for CO2 neutral or CO2 reduced mobility, so also for bus passenger transport. KWG is involved in numerous projects with permanent magnet excited generators "PMG" in the power range from 10 to 60 KW in hybrid technology for electromobility. The special type of KWG housing technology combined with the very high efficiency of the air-cooled KWG PMGs allow the "Powerpack" to be easily integrated into vehicles. "Always having your finger on the pulse of the times and being able to set the standard with your innovations makes you proud and it's really fun to be able to work on the future," says Matthias Werner (Advanced Systems Design).